Introduction to OCTG Pipes

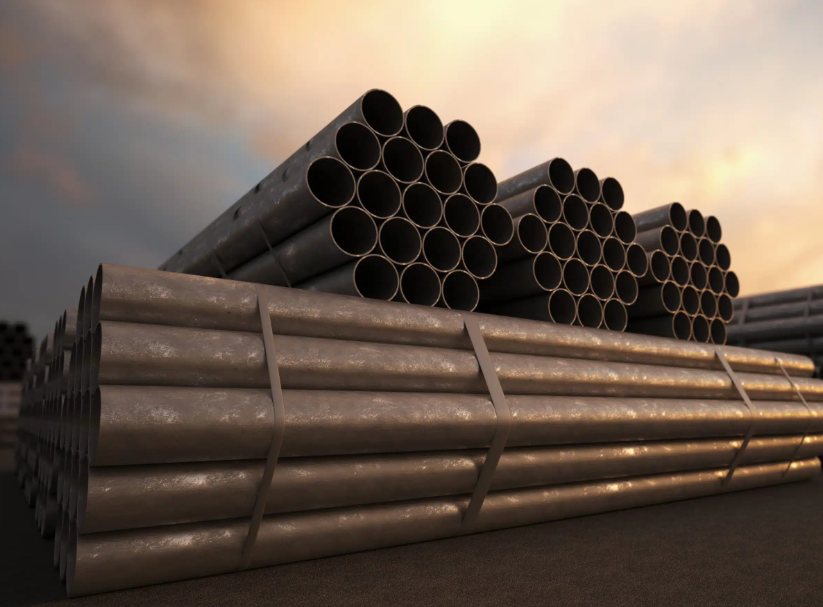

Oil Country Tubular Goods (OCTG) pipes are essential components in the oil and gas industry. These pipes are specifically designed for drilling, casing, and tubing operations in wells, ensuring efficiency, safety, and durability in extreme environments. OCTG Pipe-OCTG Casing And Tubing size chart are manufactured to withstand high pressure, temperature variations, and corrosive conditions. The two main types of OCTG pipes are casing and tubing. This article will provide an in-depth understanding of OCTG casing and tubing, including their size chart, specifications, and applications.

Understanding OCTG Casing and Tubing

OCTG Casing

Casing is a large-diameter pipe inserted into a wellbore to maintain the well’s integrity and prevent collapse. It serves as structural support for the well and helps in isolating different underground formations to prevent contamination.

There are several types of casing used in drilling operations. Surface casing is installed at shallow depths to protect freshwater sources and stabilize the well. Intermediate casing provides additional support and helps in isolating problematic formations. Production casing, which is the final casing, ensures the structural integrity of the well during hydrocarbon production.

OCTG Tubing

Tubing is a smaller-diameter pipe that transports extracted oil and gas from the wellbore to the surface. Unlike casing, tubing is exposed to production fluids and must be capable of withstanding internal pressure variations. It is installed within the casing and plays a crucial role in maintaining efficient production operations.

There are different types of tubing connections. External Upset End (EUE) tubing features thickened pipe ends to enhance strength. Non-Upset End (NUE) tubing, in contrast, has standard pipe ends without additional reinforcement. Premium connections are used in specialized applications where high pressure and mechanical integrity are crucial.

OCTG Casing and Tubing Size Chart

The selection of casing and tubing sizes depends on factors such as well depth, pressure conditions, and operational requirements. OCTG casing sizes typically range from 4 1/2 inches to 20 inches in outer diameter, with varying nominal weights depending on the grade and wall thickness. Heavier casing is used for deep wells and high-pressure environments, while lighter casing is sufficient for shallow wells.

OCTG tubing sizes generally range from 1.900 inches to 4 1/2 inches in outer diameter. The tubing’s weight per foot varies based on the material grade and thickness. Tubing used in high-pressure wells is typically manufactured from higher-strength materials to ensure longevity and reliability.

Key Factors in Selecting OCTG Pipes

Material Grades

OCTG pipes are manufactured in different material grades to suit various applications. J55 and K55 grades are commonly used for shallow wells and moderate pressure environments. N80 grade is suitable for deeper wells where higher pressure resistance is required. L80 grade is designed for corrosive environments, offering enhanced resistance to hydrogen sulfide and other corrosive elements. P110 grade is a high-strength material used in extreme drilling conditions, while C90 and T95 grades are ideal for sour service applications where corrosion resistance is a priority.

Connection Types

The type of connection used in OCTG pipes affects their performance and durability. Buttress Thread Connection (BTC) is widely used in casing applications due to its high mechanical strength. Long Thread Coupling (LTC) is preferred for deeper wells where enhanced torque resistance is necessary. Short Thread Coupling (STC) is used for less demanding applications. Premium connections, which feature advanced threading technology, are used in high-pressure, high-temperature environments.

Coating and Corrosion Resistance

OCTG pipes are manufactured according to the API 5CT specification, which sets the industry standards for material quality and performance. Corrosion-resistant alloys (CRA) are used in highly corrosive environments to extend the lifespan of the pipes. Protective coatings are also applied to OCTG pipes to reduce wear and improve performance in challenging drilling conditions.

Applications of OCTG Casing and Tubing

Oil and Gas Exploration

OCTG pipes play a crucial role in oil and gas exploration. They provide structural support for drilling operations and ensure the safe extraction of hydrocarbons from underground reservoirs. Casing and tubing are selected based on the specific requirements of each well, considering factors such as depth, pressure, and fluid composition.

Geothermal Wells

Geothermal wells require specialized casing and tubing capable of withstanding extreme temperatures. High-temperature-resistant materials are used to ensure the longevity and efficiency of geothermal wells, which are often exposed to harsh conditions.

Offshore Drilling

OCTG pipes used in offshore drilling must endure extreme pressure and corrosive seawater conditions. High-strength casing and tubing are essential for maintaining the structural integrity of offshore wells. Advanced coatings and corrosion-resistant materials are frequently utilized to prevent deterioration in subsea environments.

Unconventional Wells

Horizontal and deep wells require high-strength casing and tubing to maintain well integrity. The increased mechanical stress and operational challenges in unconventional drilling necessitate the use of premium-grade OCTG pipes. Advanced connection technologies are also employed to enhance well performance and longevity.

Conclusion

OCTG casing and tubing are fundamental to the oil and gas industry, ensuring safe and efficient well operations. Selecting the right size, material grade, and connection type is crucial for optimal performance. The specifications outlined in this article provide a reference for industry professionals when making decisions regarding OCTG pipes. As technology continues to advance, innovations in material science and manufacturing techniques will further improve the performance and durability of OCTG pipes in challenging drilling environments.