The LT1 engine, introduced by General Motors in the early 1990s, is renowned for its blend of performance and efficiency. The cooling system, particularly for models produced between 1992 and 1997, plays a crucial role in ensuring the engine operates optimally. In this article, we will delve into the components, functionality, and maintenance of the 192-97 LT1 cooling system, equipping you with the knowledge needed to keep your engine running smoothly.

Overview of the LT1 Engine

The LT1 engine, a part of GM’s Gen II small block 192-97 lt1 cooling system family, features a 5.7-liter V8 configuration. It was designed for various models, including the Chevrolet Corvette, Camaro, and Firebird. The LT1 engine was notable for its innovative design, incorporating features like an Opti-Spark ignition system and reverse-flow cooling, which optimized engine temperature control.

Importance of the Cooling System

The cooling system is vital for maintaining the engine’s temperature, ensuring it runs efficiently while preventing overheating. An effective cooling system extends engine life, improves performance, and maintains fuel efficiency. For LT1 engines, particularly, the cooling system’s design is tailored to handle the unique demands of high-performance driving.

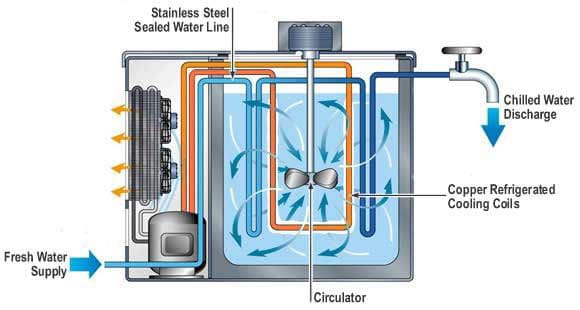

Components of the 192-97 LT1 Cooling System

The cooling system of the 192-97 LT1 is comprised of several key components. Each plays a distinct role in managing engine temperature and ensuring overall performance.

Radiator

The radiator is perhaps 192-97 lt1 cooling system the most recognizable part of the cooling system. It dissipates heat from the coolant that circulates through the engine. The LT1 features a cross-flow radiator design, which enhances cooling efficiency by allowing for better air distribution across the radiator core.

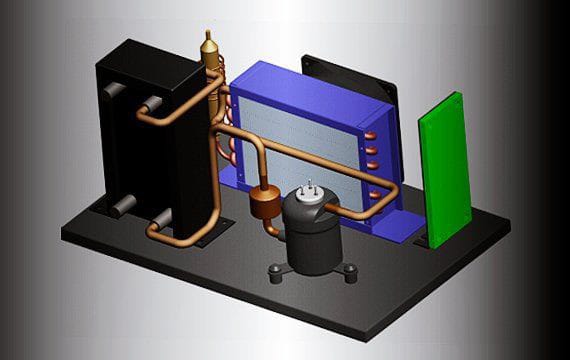

Water Pump

The water pump circulates coolant throughout the engine and cooling system. The LT1 uses a belt-driven pump, which is crucial for maintaining optimal coolant flow. This ensures that hot coolant is continually replaced with cooler coolant from the radiator.

Thermostat

The thermostat regulates the temperature of the coolant. It opens and closes at specific temperature thresholds to ensure that the engine reaches its optimal operating temperature quickly while preventing it from overheating. The LT1 thermostat is designed to maintain a temperature around 195°F (91°C) for efficient operation.

Coolant Reservoir

The coolant reservoir stores excess coolant and provides a way to monitor coolant levels. It allows for expansion and contraction 192-97 lt1 cooling system of the coolant as temperatures fluctuate, ensuring that the system remains pressurized and efficient.

Hoses and Fittings

The hoses and fittings connect all the components of the cooling system. They transport coolant between the engine, radiator, and other components. It’s essential that these hoses are inspected regularly for signs of wear, leaks, or damage.

Fan

The cooling fan is activated to pull air through the radiator when the engine temperature exceeds a certain point. The LT1 typically features an electric fan that engages based on temperature readings from the engine. This helps maintain optimal temperatures, particularly during heavy use or idling.

How the LT1 Cooling System Works

The operation of the LT1 cooling system is a 192-97 lt1 cooling system finely tuned process. As the engine runs, it generates heat due to fuel combustion. Here’s a step-by-step look at how the cooling system manages this heat:

Common Issues with the LT1 Cooling System

While the LT1 cooling system is designed for performance, it is not immune to problems. Here are some common issues that can arise:

Overheating

Overheating is a significant concern for LT1 engines. It can result from a failing water pump, clogged radiator, or malfunctioning thermostat. Regular maintenance and checks can help prevent these issues.

Coolant Leaks

Leaks can occur at various points in the cooling system, such as hoses, the water pump, or the radiator. A drop in coolant levels can lead to overheating and engine damage. Regular inspections can help identify and rectify leaks early.

Clogged Radiator

Over time, debris and sediment can accumulate in the radiator, reducing its ability to dissipate heat. Flushing the radiator periodically can help maintain its effectiveness.

Failed Thermostat

A thermostat that remains closed can prevent coolant circulation, leading to overheating. Conversely, a thermostat that opens too soon can prolong warm-up times, affecting fuel efficiency.

Maintenance Tips for the LT1 Cooling System

To ensure your LT1 cooling system remains in top condition, regular 192-97 lt1 cooling system maintenance is crucial. Here are some tips:

Conclusion

The 192-97 LT1 cooling system is a critical component in maintaining the performance and longevity of the LT1 engine. Understanding its components and how they work together is essential for any owner or enthusiast. Regular maintenance, including checking coolant levels, inspecting hoses, and flushing the system, can prevent common issues and ensure your LT1 runs smoothly.

By staying proactive about the health of your cooling system, you can enjoy the performance that the LT1 is known for while avoiding costly repairs. As with any automotive system, knowledge and diligence are your best tools for keeping your engine in optimal condition.

Also read this; emma-partnerships-and-collabs-pauls-mith

FAQs About the 192-97 LT1 Cooling System

What type of coolant should I use in my LT1 engine?

It’s recommended to use a mixture of 50/50 coolant and distilled water. Always check the manufacturer’s specifications for any specific requirements.

How often should I flush my LT1 cooling system?

Typically, it’s advisable to flush the cooling system every two years, but check the owner’s manual for any specific recommendations.

What are the symptoms of a failing water pump?

Common symptoms include coolant leaks, unusual noises from the pump area, and engine overheating. If you notice any of these signs, it’s best to have it inspected.

Can I replace the thermostat myself?

Yes, replacing the thermostat can be a DIY task if you have basic mechanical skills. Ensure the engine is cool before starting and follow a repair manual for specific instructions.

How can I prevent overheating?

Regular maintenance of the cooling system, including checking coolant levels and inspecting for leaks, can help prevent overheating. Keeping an eye on engine temperature and addressing any issues promptly is crucial.

By understanding your LT1 cooling system and adhering to maintenance practices, you can ensure a reliable and enjoyable driving experience.